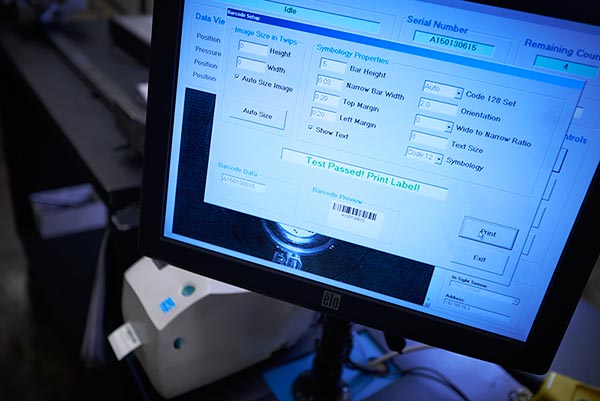

From the moment the steel is taken off the truck, it is received into the Materials Requirements Planning (MRP) system. All of its specifications; material type, poundage, heat number, country of origin, and mill source are known, recorded, and traceable in the system to ensure the quality of your nuts and bolts.

Our 100% steel traceability standard designates all material with a precise internal tracking number for our own purposes. The steel is color-coded based on this internal tracking and specification and can be easily identified in the yard. Its unique heat number, traceable all the way back to the mill it came from, is how the material is issued to each job.

This advanced MRP system is fully customizable to meet the customers’ requirements or specifications. For example, if there is a particular inspection or hold point required by you, our valued customer, we have the ability to make it happen, seamlessly. We can tell you exactly when the inspection or hold happened and precisely the employee that carried it out.

VALLEY FORGE FACTS

- On staff Certified Level II Non Destructive Testing (NDT) inspector for magnetic particle & ultrasonic.

- Also, on staff Certified Level I NDT inspector for liquid penetrate.

- We can meet your testing needs by sending resources to various nationally accredited testing labs.

- Forging process monitored by thermal temperature lasers.

- Equipment is calibrated and certified to National Institute of Standards and Technology (NIST) traceable standards.

DOCUMENTED APPROVALS

- ISO 9001-2015 Certification

- Lloyd’s Register: Type Approval Certified for ¼” – 7″ diameter. Various ASTMs, including ASTM-F2482 load indicating

- Bureau Veritas: PED 97/23/EC; Annex 1 § 4.3 for various 1″– 3″ diameter fasteners. ASTM A193, A194 & A354

- Bechtel Corporation: 3SS-MFM0-00002 Meets the Mining & Metals Specification for gearless drive grinding mills

- FMC Corporation: Approved Global Supplier

- Certifications that comply with EN 10204:2004 Type 3.1

- Certifications that meet EN 10204:2004 Type 3.2 (if required)