APPLICATION:

Slew ring bearing for an Electric arc furnace (EAF) roof gantry.

LOCATION:

Texas, USA

BOLTING ISSUE

Standard studs require biannual maintenance checks, which consist of each stud being re-torqued to verify clamp load. This is a difficult, labor intensive process that can be drastically improved through the use of load indicating fasteners.

SOLUTION

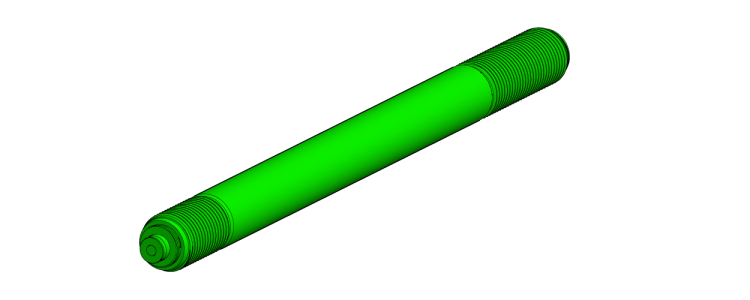

Valley Forge’s solution was the use of No-Standoff SPC4™ Load Indicating double end studs, along with a SPC4-500A mechanical load reader for routine load checks.

INSTALLATION

Using the SPC4™ Load Indicators, the actual clamp load of each stud was measured and compared to the target load. As seen in the table below, the loads achieved during initial tensioning were not only low, but also exhibited a high degree of variation. This was most notable on the inner studs, which were tensioned after the gantry structure had been lowered onto the bearing. A final pass using a single tensioner in conjunction with an SPC4-404A electronic load reader, was completed to guarantee each stud was tensioned to the desired load.

OUTCOME

SPC4™ load indicating fasteners allowed the installers to achieve proper clamp load in all 80 studs, resulting in uniform load distribution throughout the bolted joint.

Load indicating fasteners assure that the desired amount of joint pre-load has been achieved during initial installation. Also, fastener maintenance no longer requires the use of torquing equipment, but instead only the use of an SPC4™ load reader, re-torquing only as necessary.