by Rusty Flocken, Mechanical Engineer

For over a decade, Valley Forge has offered Maxbolt™ load indicating fasteners to customers requiring direct load indication. Now the same technology can be installed in fasteners which were previously too small to accommodate a Maxbolt™ indicator. The Miniature Maxbolt™ was originally developed for a customer requiring fitment into a 5/8” diameter hex cap screw for mounting on a rail-car. For the first time ever, this customer has been able to record and catalog actual bolt loads over time using a spreadsheet. This information can be used to highlight special characteristics such as a bolt’s behavior as a function of its position within an assembly, or maintenance activities which may change bolt loads. The information can also be used, in general, to categorize overall behaviors of the joint such as embedment. This phenomenon and others occur on an average over the sum of all bolts in the joint, and can greatly affect joint performance over time.

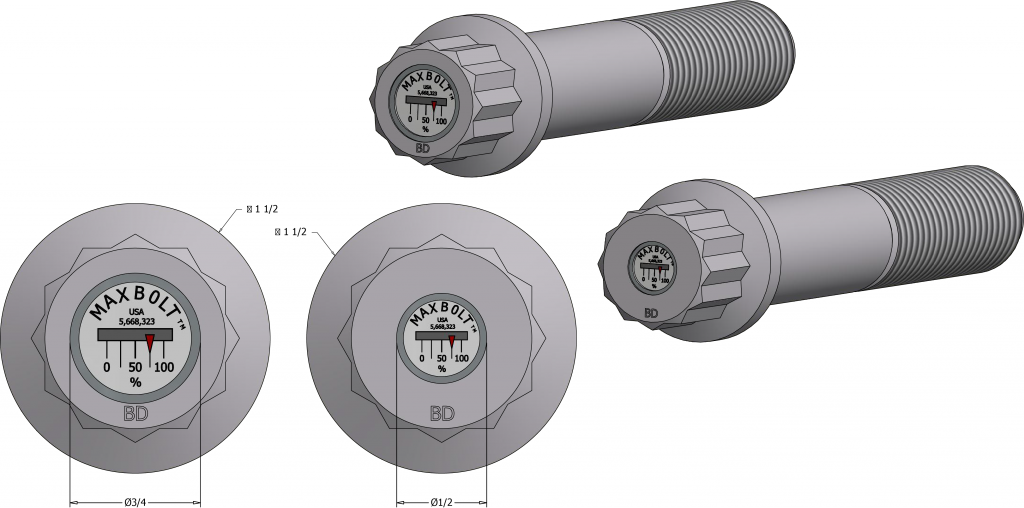

The Miniature Maxbolt is set apart from previous Maxbolt™ designs in that the primary goal was to create the most compact indicator possible in order to reduce the impact of material removal on small bolts. This is our only Maxbolt™ designed to use a smaller 0.1875 diameter gage pin, allowing for less reduction in cross-sectional area. The Miniature Maxbolt™ can be installed into bolts as small as 5/8” [M16], installations can also be made in 3/4” [M20] bolts, with the added benefit of less de-ration when compared to a standard Maxbolt™. Both sizes of bolts will require an increased head height to accommodate the Maxbolt™ indicator.